PAGE 2

Application of Welded Reinforcing Cage System

|

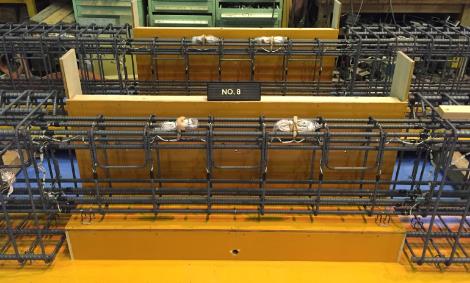

Welded Reinforcing bar Recently, reinforced concrete footing beams using welded connections between main reinforcing bars and stirrups have been popular for low-rise RC buildings and wooden houses. Using the welded connections, workers at construction field can easily arrange steel bars. To use the welded connections for wider footing beams in which double-layered main bars are arranged, a cap-tie system for welded main bars-stirrups is newly proposed. At first, main bars and stirrups are welded and formed to mesh-shape by flash welding using the dedicated machine. After that, the mesh-shape bars are folded as to be U-shape. This U-shape bars consist of main bars and the lower part of stirrups of footing beam. In case of ordinary arrangement for beams, stirrups have 135 degree hooks to anchor the stirrups to the main bars. In case of the proposed system, stirrups are fixed and anchored only by welding. Cap-tie is set to confine the upper main bars after placing the U-shape bars into the mold. Cap-tie has also the anchorage part by welding bars or 90 degree hooks that are formed in 3-dimensional shape. |

|

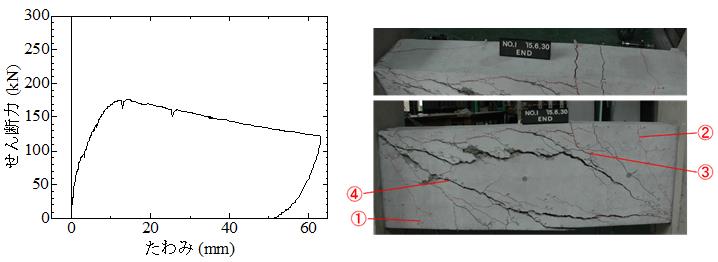

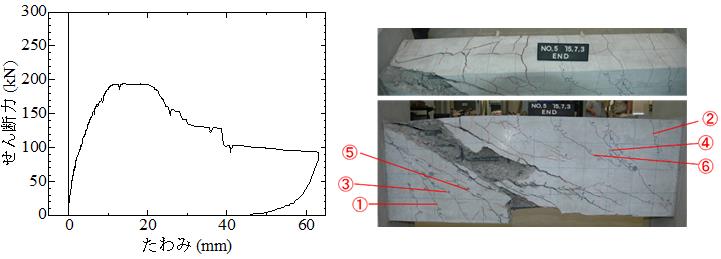

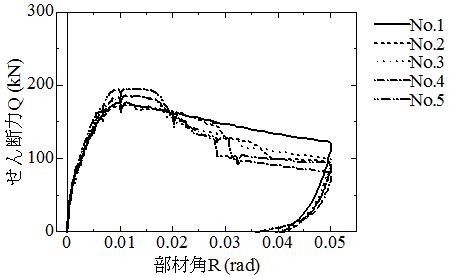

Experimental test for footing beams The purpose of this study is to investigate shear performance of RC footing beams manufactured by proposed cap-tie system. The anti-symmetrical bending shear test is conducted. Main variables are concrete target strength and cap-tie type. Test specimens are designed to fail by shear to confirm the shear performance of proposed system. |

|

|

Beam specimens The specimens are designed to have similar cross-section as that of practical footing beams which have double-main bar. The cross-sectional size is 220mm x 440mm, a clear span length is 1260mm, and stubs are arranged at both ends of the specimen. Main bars at the four corners are welded with stirrups. The other main bars are fixed to the cap-tie or positioning bars with thin wire. D10 bars are used for stirrups at 200mm intervals. Concrete target strength is 18MPa and 30MPa, they are lower limit and upper limit of practical use. The specimens are designed to fail by shear to confirm the shear performance of proposed system. |

|

Loading method The specimens are subjected to anti-symmetrical bending shear moment. The 2MN universal testing machine is used for the monotonic loading. |

|

|

Test results Shear capacities of cap-tie specimens are similar or greater than those of ordinary RC specimens. Shear capacities of cap-tie specimens can be safely evaluated by existing formulas adopted for ordinary RC beams. The expansion of bond splitting cracks of cap-tie specimens is inhibited in 18MPa series specimens. It is suggested that the cap-tie system can improve the bond strength of main bars. |

|