1 Introduction

The 9/11 terrorist attack on the New York World Trade Center (WTC) towers caused

an unprecedented tragedy in the history of architecture. The twin towers WTC 1 and 2 stood in flames caused by jet fuel until

finally, both collapsed totally to the ground with thousands of people

trapped in the buildings. Both towers collapsed at an unnaturally high

speed, which was observed to be nearly equal to that of free fall. Official

statements have already been released by the Federal Emergency Management

Agency (FEMA) in 2002 [1], and also by the National Institute of Standards

and Technology (NIST) in 2005 [2], regarding the incident. FEMA [1] concluded

that the heat of burning jet fuel induced additional stresses into the damaged structural

frames while simultaneously softening and weakening these frames, and this

additional loading and the resulting damage were sufficient to induce the

collapse of both structures. Many detailed numerical analyses were carried

out in [2], and the report was concluded by stating gthe WTC towers likely

would not have collapsed under the combined effects of aircraft impact

damage and the extensive, multifloor fires, if the thermal insulation had

not been widely dislodged or had been only minimally dislodged by aircraft

impact.h However, did the fire really spread to such a wide range in the

buildings to cause the total collapse? Moreover, was the heat high enough

to reduce the strengths of structural members? What really caused the free-fall

total collapse? Many questions still remain unresolved. Also, it is to

be noted that although many detailed analyses were performed in [2], not

even a single result can be found showing the dynamic behaviors of the

towers during aircraft impact (Fig. 1). It is clear that the towers experienced

an extreme dynamic load that no other high-rise building has ever experienced

in history. Therefore, we performed

some aircraft impact analyses of a full-model WTC tower, to determine the possibility

of the impact itself acting as a fatal cause of the collapse.

Figure 1. Aircraft impact on WTC 2 [2].

The numerical code used in the

analyses is based on the ASI-Gauss technique [3], which was developed and modified

by Isobe et al., from the adaptively shifted integration (ASI) technique

[4] for the linear Timoshenko beam element. It enables the computation of

highly accurate elastoplastic solutions even with the minimum number of

elements per member. In this paper, we first describe an outline of the

technique and the modeling of the WTC tower, followed by some numerical results

on WTC 2, for which some observed data are available and easy to verify.

2 Numerical Code

2.1 ASI-Gauss Technique

Toi and

Isobe developed the ASI technique [4-6] for the linear Timoshenko beam and

Bernoulli-Euler beam elements, which can easily be incorporated into existing

finite element codes. In this technique, the numerical integration point is

shifted immediately after the occurrence of a fully plastic section in the

element so that a plastic hinge is formed exactly at that section. As a result,

the ASI technique gives more precise elastoplastic solutions than the

conventional schemes, and enables us to simulate dynamic behaviors with strong

nonlinearities using only a small number of elements for a member.

Figure 2. Linear Timoshenko beam element and its physical equivalent.

Figure 2 shows a linear Timoshenko beam element and its physical equivalence

to the rigid bodies-spring model (RBSM). As shown in the figure, the relationship

between the locations of the numerical integration point and the stress

evaluation point where a plastic hinge is actually formed is expressed

as [7]

![]() .

(1)

.

(1)

In the above equation, s is the location of the numerical integration point

and r is the location where stresses and strains are actually evaluated. s is a

nondimensional quantity, which takes a value between -1 and 1.

In both the ASI and ASI-Gauss techniques, the numerical integration point is shifted adaptively when a fully plastic section is formed within an element to form a plastic hinge exactly at that section. When the plastic hinge is determined to be unloaded, the corresponding numerical integration point is shifted back to its normal position. Here, the normal position means the location where the numerical integration point is placed when the element acts elastically. By doing so, the plastic behavior of the element is simulated appropriately, and the converged solution is obtained with only a small number of elements per member. However, in the ASI technique, the numerical integration point is placed at the midpoint of the linear Timoshenko beam element, which is considered to be optimal for one-point integration, when the entire region of the element behaves elastically. When the number of elements per member is very small, solutions in the elastic range are not accurate since one-point integration is used to evaluate the low-order displacement function of the beam element.

The main difference between the ASI and ASI-Gauss

techniques lies in the normal position of the numerical integration point. In

the ASI-Gauss technique, two consecutive elements forming a member are

considered as a subset, and the numerical integration points of an elastically

deformed member are placed such that the stress evaluation points coincide with

the Gaussian integration points of the member. This means that stresses and

strains are evaluated at the Gaussian integration points of elastically

deformed members. Gaussian integration points are optimal for two-point

integration and the accuracy of bending deformation is mathematically

guaranteed [8]. In this way, the ASI-Gauss technique takes advantage of

two-point integration while using one-point integration in actual calculations.

Figure 3. Locations of numerical integration and stress evaluation points in elastic range.

Figure 3 shows the locations of the numerical integrations points of elastically

deformed elements in the ASI and ASI-Gauss techniques. The elemental stiffness

matrix, generalized strain and resultant force increment vectors for the

ASI technique are given by Eqs. (2a)-(2c) and those for the ASI-Gauss technique

by Eqs. (3a)-(3c).

![]() (2a)

(2a)

![]() (2b)

(2b)

![]() (2c)

(2c)

![]() (3a)

(3a)

![]() (3b)

(3b)

![]() (3c)

(3c)

Here, ![]() ,

, ![]() and

and ![]() are the generalized strain increment vector, generalized stress (resultant

force) increment vector and nodal displacement increment vector, respectively.

sg and rg are the locations of the numerical integration and stress evaluation points

for the ASI-Gauss technique in the elastic range. They take values as shown

in Fig. 2. [B] is the generalized strain-nodal displacement matrix, [D]

is the stress-strain matrix and L is the length of the element.

are the generalized strain increment vector, generalized stress (resultant

force) increment vector and nodal displacement increment vector, respectively.

sg and rg are the locations of the numerical integration and stress evaluation points

for the ASI-Gauss technique in the elastic range. They take values as shown

in Fig. 2. [B] is the generalized strain-nodal displacement matrix, [D]

is the stress-strain matrix and L is the length of the element.

The plastic potential used in this study is expressed

by

![]() . (4)

. (4)

Here, fy is the yield function, and Mx , My, N and Mz are the bending moments around the x- and y-axes, axial force and torsional moment, respectively. Those with the subscript 0 are values that result in a fully plastic section in an element when they act on a cross section independently. The effect of shear force is neglected in the yield function.

2.2 Member Fracture and Contact

Algorithm

Structurally

discontinuous problems have also become easily handled in the ASI and ASI-Gauss

techniques, by shifting the numerical integration point of the linear

Timoshenko beam element to an appropriate position, and by releasing the

resultant forces in the element simultaneously [3,6]. Elemental contact is

considered in the code by introducing gap elements between two elements

determined to be in contact by geometrical relations. More details on the code

can be found in [3-6].

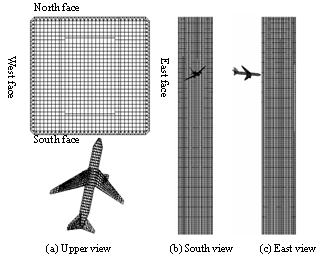

Figure 4. Analyzed model.

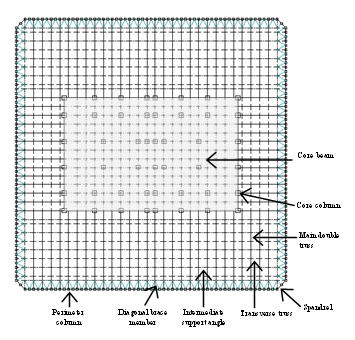

Figure 5. Cross section of the WTC towers.

3

Numerical

Model and Analytical Conditions

3.1 Numerical Model

A full model of the WTC tower is constructed to investigate the overall effect of aircraft impact on the building. Details on the structural members and construction data are extracted and adopted from the reports [1,2]. The tower and the B767-200ER aircraft are both modeled with linear Timoshenko beam elements, of which all members are subdivided into two elements. Figure 4 shows a schematic view of the WTC 2 tower model and the aircraft model. The tower model contains 604,780 elements, 435,117 nodes and 2,608,686 degrees of freedom, while the aircraft model contains 4,322 elements, 2,970 nodes and 17,820 degrees of freedom. Figure 5 shows a cross-sectional view of the towers. A floor is roughly divided into two sections, external and core structures, each with different roles from the structural point of view. The external structure is mainly designed to sustain wind loads, while the main double trusses connected to the core structure support all the floor loads. The whole tower is subjected to a designed dead load of 2,890 MN and 40 % of the allowed capacity load, 300 MN. The ratio of the loads between the core and external structures is adjusted to become approximately 6:4 [1].

All structural members of the B767-200ER aircraft are assumed to have box-shaped cross sections and the material properties of extra super duralumin. The total mass of the aircraft at the time of impact is 142.5 t, which is the sum of the masses of the aircraft (112.5 t) and the jet fuel (30 t) [1]. The mass of each engine is assumed to be 19.315 t. The nose of the aircraft

is tilted 11.5 degrees to the east and 5 degrees downward, and its left wing is

inclined downward by 35 degrees. It is assumed to collide with the 81st floor, south face of WTC 2 with a cruise speed of 590 mph (262 m/s).

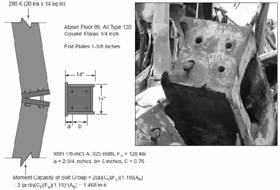

Figure 6. Typical column joint of WTC towers [1].

3.2 Analytical Conditions

Most of the column joints were connected with 34-mm-thick end plates attached by 4 to 6 bolts (Fig. 6). The joints were weak against flexural and shear forces; the simple moment capacity of the bolt group was 20 to 30 % of the plastic moment capacity of the column itself [1]. The beam joints of main double trusses also had simple connections to sustain static, vertical dead loads, which satisfied the initial structural design. The structural design of member joints in Japan, for example, demands the capacity to be greater than that of the member itself. In the present study, the vulnerability of member joints are considered by introducing fracture conditions as follows [3]:

![]() ,

(5)

,

(5)

where ![]() ,

, ![]() ,

, ![]() ,

, ![]() ,

, ![]() and

and ![]() are the bending

strains around the x- and y-axes, the axial tensile strain and the critical values for these three strains, respectively. We

fixed the critical axial tensile

strain

values by comparing the impact damage and motion of the

engines with the observed data. We still need to discuss

critical bending strains in the future, since member joint characteristics are currently

not well known.

are the bending

strains around the x- and y-axes, the axial tensile strain and the critical values for these three strains, respectively. We

fixed the critical axial tensile

strain

values by comparing the impact damage and motion of the

engines with the observed data. We still need to discuss

critical bending strains in the future, since member joint characteristics are currently

not well known.

We also considered the strain

rate effect on yield strength using the Cowper-Symonds equation [9]. An implicit scheme with a consistent mass matrix is adopted in this study. No

damping except for the algorithmic one is applied. ![]() is set to 5/6 and

is set to 5/6 and ![]() to 4/9 in Newmarkfs

to 4/9 in Newmarkfs ![]() method. The time increment

method. The time increment ![]() t is set to 0.2 ms. An updated Lagrangian formulation is used since large deformations are

expected in the analysis, and the conjugate gradient (CG) method is used as the

solver to reduce the memory requirement. The analytical

code is run on a high-performance computer (1.4

GHz Itanium*2, 8GB RAM), and the

calculation takes approximately two months for a physical

time of 0.7 s.

t is set to 0.2 ms. An updated Lagrangian formulation is used since large deformations are

expected in the analysis, and the conjugate gradient (CG) method is used as the

solver to reduce the memory requirement. The analytical

code is run on a high-performance computer (1.4

GHz Itanium*2, 8GB RAM), and the

calculation takes approximately two months for a physical

time of 0.7 s.

(a)

0.12 s, (b) 0.28 s and (c) 0.56 s after impact

Figure 7. Aircraft impact analysis of WTC 2 (global view).

(a)

0.12 s, (b) 0.28 s and (c) 0.56 s after impact

Figure 8. Motion of fuselage and engines (upper view).

4 Aircraft

Impact Analysis of WTC 2

The numerical results are shown in Figs. 7 and 8. Movie files movie 1 movie 2 can be downloaded at the website [10] . The left engine reduces its speed

rapidly as it directly enters the core structure. The right engine, on

the other hand, glances off the core structure and goes out of the north-east

corner of the tower. Table 1 shows the impact timeline of the fuselage

and both engines. The velocity curve of the right engine is shown in Fig.

9 and a comparison of the damaged surfaces between the numerical result

and the observed data [2] is shown in Fig. 10. Both results are in good

agreement with the observed data.

Table 1: Impact timeline of the B767-200ER aircraft

|

@ |

@ |

B767-200ER aircraft |

||

|

Phase |

Elapsed time (s) |

Left engine |

Right engine |

Snout |

|

@ |

0 |

Snout hits outer-perimeter wall |

||

|

A |

0.048 |

@ |

@ |

Hits core structure |

|

@ |

0.072 |

Hits outer-perimeter wall |

@ |

@ |

|

B |

0.076 |

@ |

Hits outer-perimeter wall |

@ |

|

C |

0.128 |

Hits core structure |

@ |

@ |

|

D |

0.168 |

Hits core column No.902 |

@ |

@ |

|

E |

0.504 |

Hits core column No.903 |

@ |

@ |

|

F |

0.512 |

@ |

Hits east side outer-perimeter wall |

@ |

Figure 9. Velocity curve of the right engine.

(a) Numerical result (b) Observed data [2]

Figure 10. Damage of the WTC 2 south face.

The dynamic transition of the resultant forces during impact is investigated.

Figure 11 shows the transition of axial forces in two typical core columns,

at the site of every ten stories from the ground floor to the top floor.

Core columns are compressed constantly until the snout reaches the core

structure (Phase A in the figures), after which a wave due to impact and

member fracture propagates in horizontal and vertical directions. In particular,

the compression decreases instantly in the fractured core column (No. 1001)

at the floors above the impact point. At the lower levels, compression

changes to tension immediately after the left engine hits the core structure

(Phase C), and continue to vibrate with large amplitude. Note that the

lower the level goes, the larger the amplitude becomes. The core column

(No.1001) at the 60th floor, for example, is heaved for 25 cm in 0.2 s

as a result of this dynamic transition.

Figure 11. Time histories of axial forces in core columns No.508 and No.1001.

Figure 12. Distribution of fractured main double trusses.

What actually caused this dynamic unloading large enough to generate such

large tensile forces? We extracted the time history of the distribution

of fractured main double trusses, as shown in Fig. 12, to investigate the

cause. The propagation of fractured trusses from the impact point to upper

and lower levels can be observed in the figure. This propagation speed

almost matched the longitudinal wave speed in the columns. It can be assumed

that the shock wave due to impact propagated through the tower and occasionally

reflected to other columns at the ground or top levels, destroying each

member joint as it moved on. Our assumed scenario is as follows; the aircraft

impact destroyed several main double trusses, that supported the floor

slabs, and led to a middle-class unloading of core columns. The deformation

due to the unloading caused other trusses to disconnect, which released

further burden from the core columns. This disconnect-and-release process

advanced rapidly in a chain reaction manner and a spring-back phenomenon

might have occurred in many columns in such a way that a compressed spring

is released in a very short moment. It was fatal enough to produce a gigantic tensile force on

the columns, which might have triggered the total fracture of some column joints,

eventually leading to the total collapse of the towers. It can be assumed that

the damage in lower levels was larger, since the lower the level went, the larger

the tensile force became.

5 Conclusion

The assumptions of member joint strength given in this work may not be

sufficient for making any clear statements. However, there is a possibility

that the spring-back phenomenon due to rapid unloading caused by aircraft

impact acted as a fatal cause of the total collapse of the WTC towers.

Further numerical investigations performed by explicitly modeling the behaviors

of member joints, and also for the case of WTC 1 are in progress.

6 Acknowledgements

This work was partially supported by a Grant-in-Aid

for Scientific Research (No.#16206055),

Japan Society for the Promotion of Science. The author also would like to thank Zion Sasaki and Kyaw Myo Lynn, former

graduate students of his lab, for contributing greatly to this work.